On June 3rd 2024, Neural Concept, an Engineering Intelligence platform that transforms product design for manufacturers with 3D Deep Learning, announced that it has raised $27 million in a Series B funding round. The round was led by Forestay Capital, with the D. E. Shaw group and existing investors also participating. Investing once again within the realm of Enterprise SaaS, the deal represents Forestay’s third in its second Fund and the fourth to arise from an EPFL spin-off.

For Forestay, it all started by building conviction in the AI-enabled simulation space as the team conducted deep research on the potential impact of AI & ML within the realm of Industrial Technology. It rapidly came to light that when it comes to physics-based simulation software, the emergence of legacy CAE/CAD technology can be tracked back to the 60s. However, progress in the space has since been incremental and hindered by limited application of machine learning. Advancements in the realms of AI, Big Data, and Machine Learning, paired with the ever-improving foundational hardware enabled considerable development in the space of AI-enabled CAD/CAE, which prompted us to take a closer look at emerging players within the space. When assessing the roster of modern, AI-enabled solutions, we understood that Neural Concept was not only years ahead in terms of product development but was also able to address the pain points of manufacturers from various industries right from the start (contrary to most verticalized competitors).

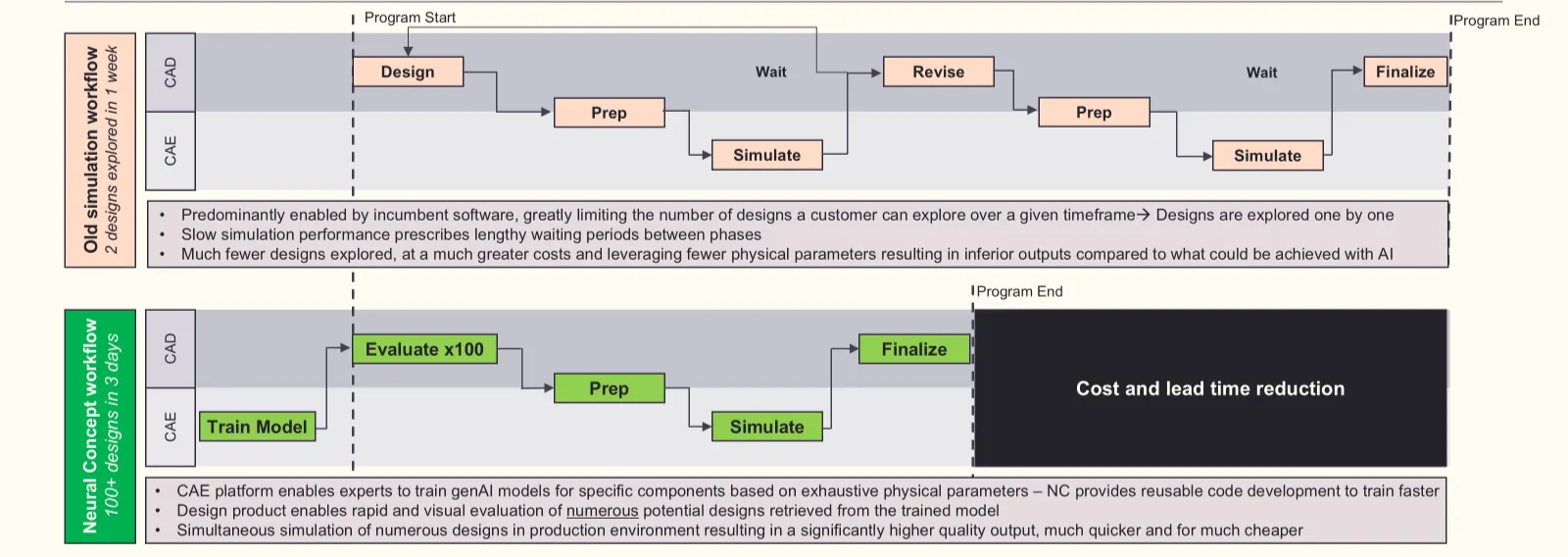

Neural Concept is a category-leading, Engineering Intelligence software using machine learning and neural networks at its core to significantly accelerate physics-based simulation workflows enabling the design of better products, faster and at a lower cost for industrial companies. The product is built on a unique 3D shape-optimization technology, which, paired with customer data, provides highly tailored, precise, and visual product simulations. Traditionally, engineering design involves teams of highly skilled designers and engineers working together to come up with new and innovative designs, subsequently simulated in various working environments to identify strengths and weaknesses. This process is repeated until the results are satisfactory.

In contrast, by using Neural Concept, these teams can generate and simulate hundreds of designs at a time and ultimately validate superior concepts with higher levels of confidence, while making considerable cost and time savings.

The speed, precision and reliability provided by the product collectively amount to a revolution within the space of Computer-Aided Design and Engineering (CAD/CAE). The resulting elevated ROI allowed the young company to rapidly secure robust recurring contracts with some of the largest manufacturers globally, across the Aerospace, Consumer Electronics, Energy, Automotive and Semiconductor industries.

In order to do so, Pierre Baqué, Co-Founder, CEO and inventor of this technology, has been fortuitously implementing a simple and effective go-to-market strategy, selling a highly complex technology to large and traditionally slow-moving industrial customers. Throughout this journey, Pierre has not only been able to step up personally across the company’s early phases of growth but has successfully surrounded himself with ambitious people sharing a simple and pragmatic approach to doing things, whilst managing the technology’s complexity in the background.

Today, manufacturers globally are facing unprecedented challenges. The need for improved performance, safety, and sustainability is increasing, while pressure to reduce costs and accelerate innovation continues to rise. Without proper Engineering Intelligence capabilities in-house, Forestay believes that manufacturers will see their sources of competitive advantage erode in the long run. Additionally, Engineering Intelligence, when rightly implemented, is starting to provide end simulation results that engineers themselves are not able to replicate. However, while the urgency to adopt and build an AI stack is increasingly felt, this involves considerable implementation and change management challenges that software vendors must embrace in order to efficiently establish themselves as a mission-critical standard in the space.

Overall, it is Forestay’s strong conviction that the applications of AI and machine learning in Industrial Technology will help manufacturers pivot towards a data-driven business model, where the application of modern technology will provide superior results and insights to maintain and strengthen their competitive positioning.